Designer Nathan Martell shows us the creation of his light from prototype to finished product.

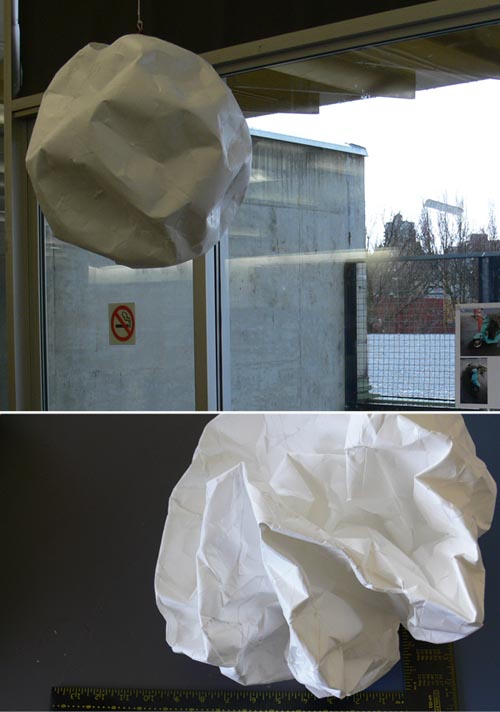

The evolution of my lighting prototypes (some missing, as they were modified to the point of disintegration).

The focus of the project took shape after analysis of this first prototype. Prototype one was humble in its materials and production method, utilizing copy paper and a glue based paper mache technique over a standard balloon. The simplicity of the paper mache allowed me to, feasibly and economically, experiment with real materials at full scale, a liberating rarity.

These images depict a major turning point. After several more dissatisfying small balloon size prototypes, I decided to change scale. Oddly enough, I initially decided to use strips to simply save time in the prototyping process (I could cut multiple sheets at once) but this ended up strongly informing the prototypes to follow. This prototype was still made using copy paper and glue and was formed over a large spherical balloon.

I was pleased with the outcome, however, I was not sold on the idea of shipping a large box filled with 99% empty space. My adviser at the time also suggested that it may not fit through some doorways. He then told me “make it fit inside a pizza box,” and that became the challenge of the second half of the project.

My proposed solution was to build the light at full scale, fold it down to fit inside the box, and then somehow expand it once it reached its destination. It became very obvious, that copy paper would no longer serve the purpose. Parchment paper was used for this prototype. It allowed for a certain amount of compression while still being able to return to its original form, however, it was prone to tearing and was overall, far too fragile. The wrinkled texture created from compressing it reminded me of a jacket I used to own made from Tyvek, a paper-like synthetic textile.

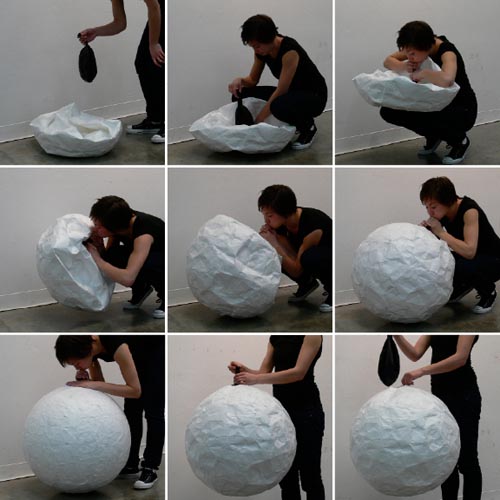

Using Tyvek I made this model. It was able to be compressed to roughly 1/5th of its size and proved to be impressively resilient. I had been debating over how the light would be expanded after compressing it to ship, until the most obvious solution finally made itself visible to me.

Each light is packed flat and shipped with a balloon, the form is then ‘reinflated’ by the end user.

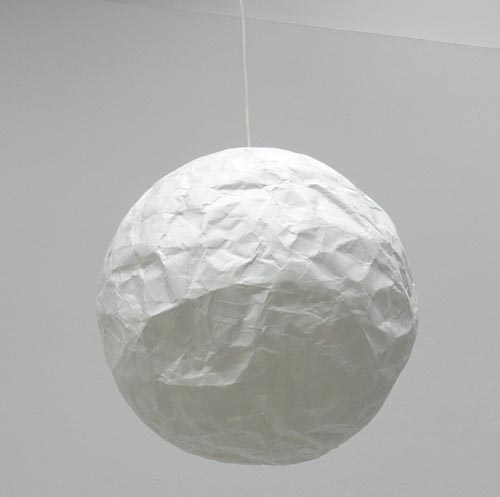

For the final product, the process is not much different than the paper mache technique used in prototype one. Tyvek strips are soaked in a watered down adhesive and wrapped around a large spherical balloon. Repeated compressions of the form do not weaken the structure, rather, doing so simply adds layers of texture to the object.

I am currently working on the hardware/fittings, as well as new ways of production that will allow the light to be more efficiently mass manufactured.

If you would like to be kept informed as to the availability of the light, please email [email protected]. I Invite you to come take a look at some of my other work as well.