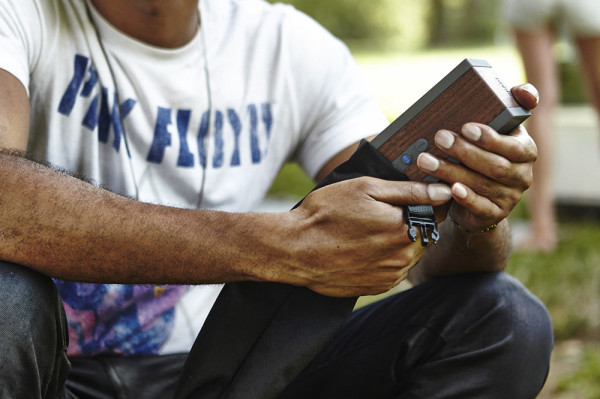

The Packable Wireless System (PWS.01) was conceived of as a great sounding speaker with a simple form, rendered in a mix of solid wood and other highly tactile materials. The goal was to make the PWS comfortable in the hand and hard to put down. The images below will walk you through the design and manufacturing process of the speaker.

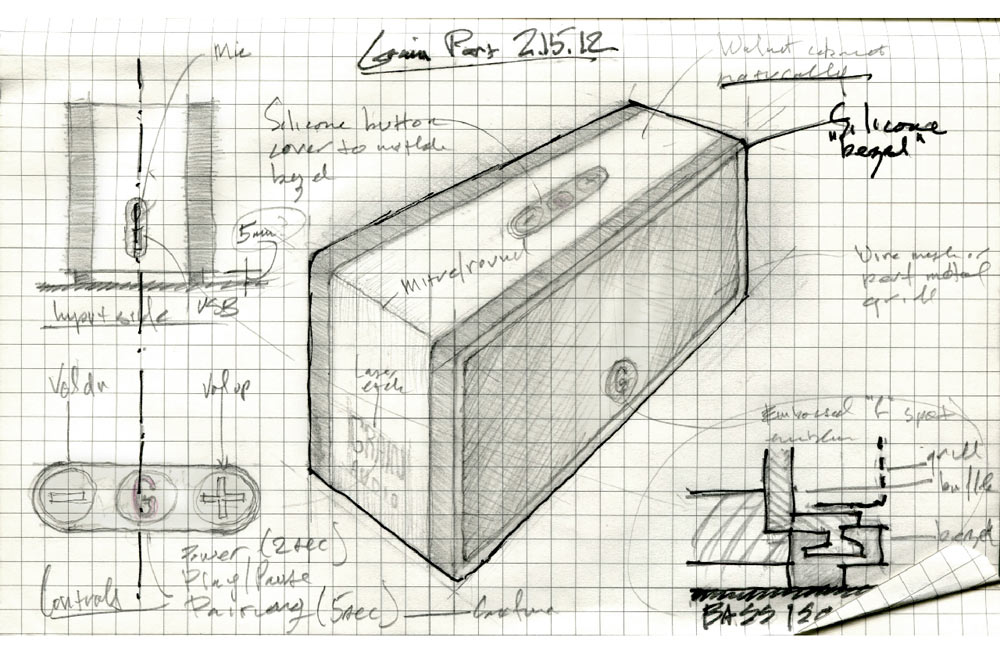

1. Sketch

The above sketch shows how the project started with a simple drawing indicating the shape, and several notes about materiality and detail direction. As with all of Grain Audio’s products, the smallest details are very important and always considered early on in the process. In fact, the concept of our “Bass Isolation” foot, shown in the lower right hand corner of the sketch, was the starting point for this design.

2. First Rendering

From the initial sketch, the design went into a digital model to further sort out details and to begin to test finishes and general scale. This image also shows some branding that never made it into the final version.

3. Mock-Ups

While developing the digital model, we also made many physical mock-ups to test size, wood species, and grill materials. These ranged from simple cardboard shapes to test general ergonomics, to more detailed wood models as the product developed.

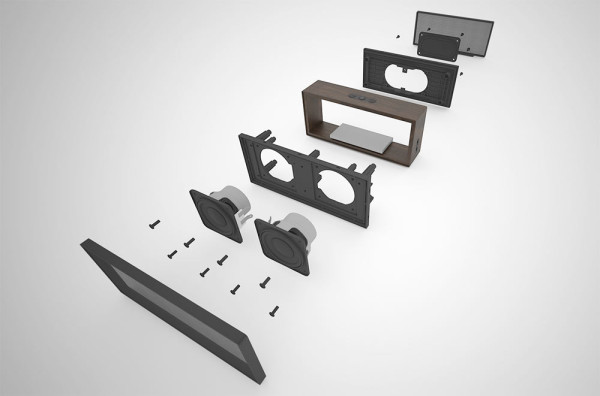

4. Exploded

The digital modeling phase was also used to define the direction of the mechanical engineering of the PWS. This rendering shows the engineering concept for the PWS, a solid wood exterior ring supported by an inner frame. We developed this in-house and worked with our manufacturer to finalize the assembly in later development phases.

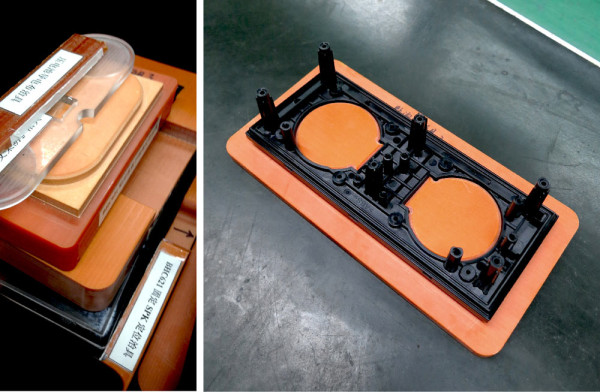

5. Prototyping

These are images of the first prototype from our manufacturer. The internal frame was printed along with the separate supporting structures that were added to hold the internal battery, circuitry, and inputs. This was a great meeting.

6. Cabinets

The wood enclosure is the signature of the PWS. It feels great, has a beautiful effect on the sound quality of the unit, and lends an individual character to each built unit. This image shows a selection of solid walnut cabinets being sorted for a pre-production run.

7. Soft Parts

The PWS was an exercise in material restraint. Besides the wood surround and perforated metal grill, the only other material on the product is molded silicone. This was chosen for its tactile qualities in areas like the button cover and for its performance characteristics on the grill surround.

8. Jigs

Using wood has its drawbacks too. Getting a wood vendor to deliver housings with a tolerance as tight as our plastic parts has been a challenge. This can wreak havoc on a production line trying to get parts to align. To help with this we have worked with our manufacturer to develop assembly jigs for each step of the production. These extra steps assure the fit and finish that we have promised our customer.

9. Units off the line

This image shows the first units coming off of a pre-production line.

10. Finished product!

* Get 10% a Grain PAW using special coupon code GRAINDM10 here (now through Christmas).