On a scale from 1-10, the hype about the potential of 3D printing has reached a fevered mark deserving a Spinal Tap-ian “11”. But where the excitement may be deserved and development may prove revolutionary is within the field of prosthetic devices and orthopedic healing aids.

MHOX and CRP Group collaborated with medical professionals to develop highly fit-customizable 3D printed generative orthoses.

An orthosis is a medical apparatus applied externally to the human body to modify the structural and functional characteristics of the neuromuscular and skeletal system. You might have worn one after breaking an arm or leg, injuring a hand or neck, and if so, likely remember how restrictively cumbersome they felt. Cue in 3D printed devices designed to “assist, restrict, control or limit movement for specific body segments” in ways previously unavailable using traditional post-surgical devices (e.g., braces, splints and casts).

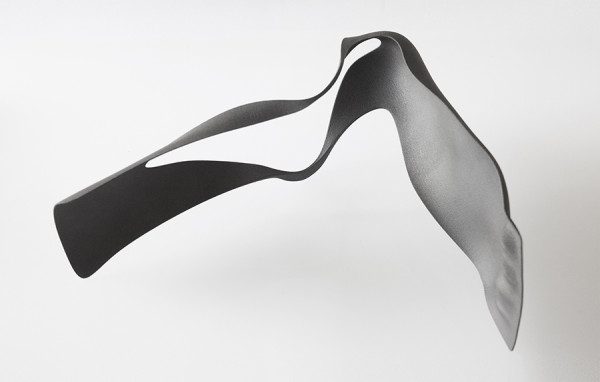

A highly flexible leg orthosis made of polyamide-based material reinforced with glass fibers is designed to hug both leg and the foot while still allowing natural motion to provide active support and control in the gait cycle while healing.

MHOX and CRP Technology turned to 3D printing and an additive material process to manufacture a next generation of orthosis created in three phases:

- a precise body scan is made of the patient’s body part

- a 3D orthosis plan is developed for perfect custom fit for the wearer

- a 3D printer can then produce a flexible and washable orthosis, offering a fit well beyond the traditional range of small, medium, large and x-large

The biomorphic shapes produced from 3D scans and printers hug each contour of scanned body parts, reducing irritation caused by poorly fit devices and improving the range of motion allowed while wearing orthotics.

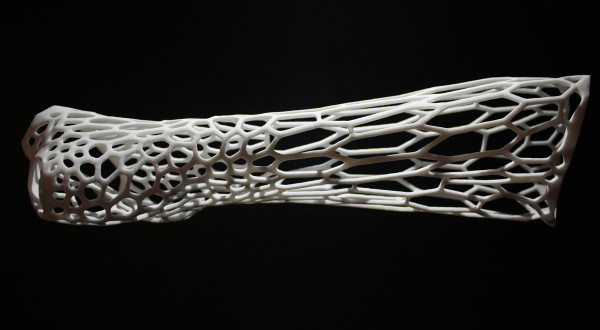

Bespoke polyamide 3D printed casts like the Cortex cast designed by Jake Evill liberate wearers from the cumbersome plaster casts used today.

Bearing a similar wireframe geometric design to the Cortex cast, industrial designer Deniz Karasahin‘s Osteoid supplements healing of bone using Exogen, a low-intensity ultrasound system.

“We typically think of design as design, and medicine as medicine, though in many cases, good design simply becomes good medicine” – Scott Summit, 3D Systems designer of Bespoke Braces.

3D Systems Bespoke Braces designed for chronic condition scoliosis proved highly desirable amongst children and young adults afflicted with the abnormal spinal curvature not only because of its comfortable fit/flexibility, but in no small part because the matrix pattern design was considered an aesthetic/fashionable upgrade.

Although signing a cast for a broken arm or leg has long been a rite of passage, in reality, living and moving encased inside one can prove stifling over the time required for bones to set and heal (not to mention the smell that ferments within!). The new generation of 3D printed orthotics (and prosthetic) devices are widening the range of movement available to wearers, making for a more comfortable healing process, while also improving air flow to body parts which often become unpleasantly sweaty and itchy while bound in bandage or plaster casts.

There’s a good chance in the near future we won’t be having our casts signed by friends and family, but we’ll have them 3D engraved instead.