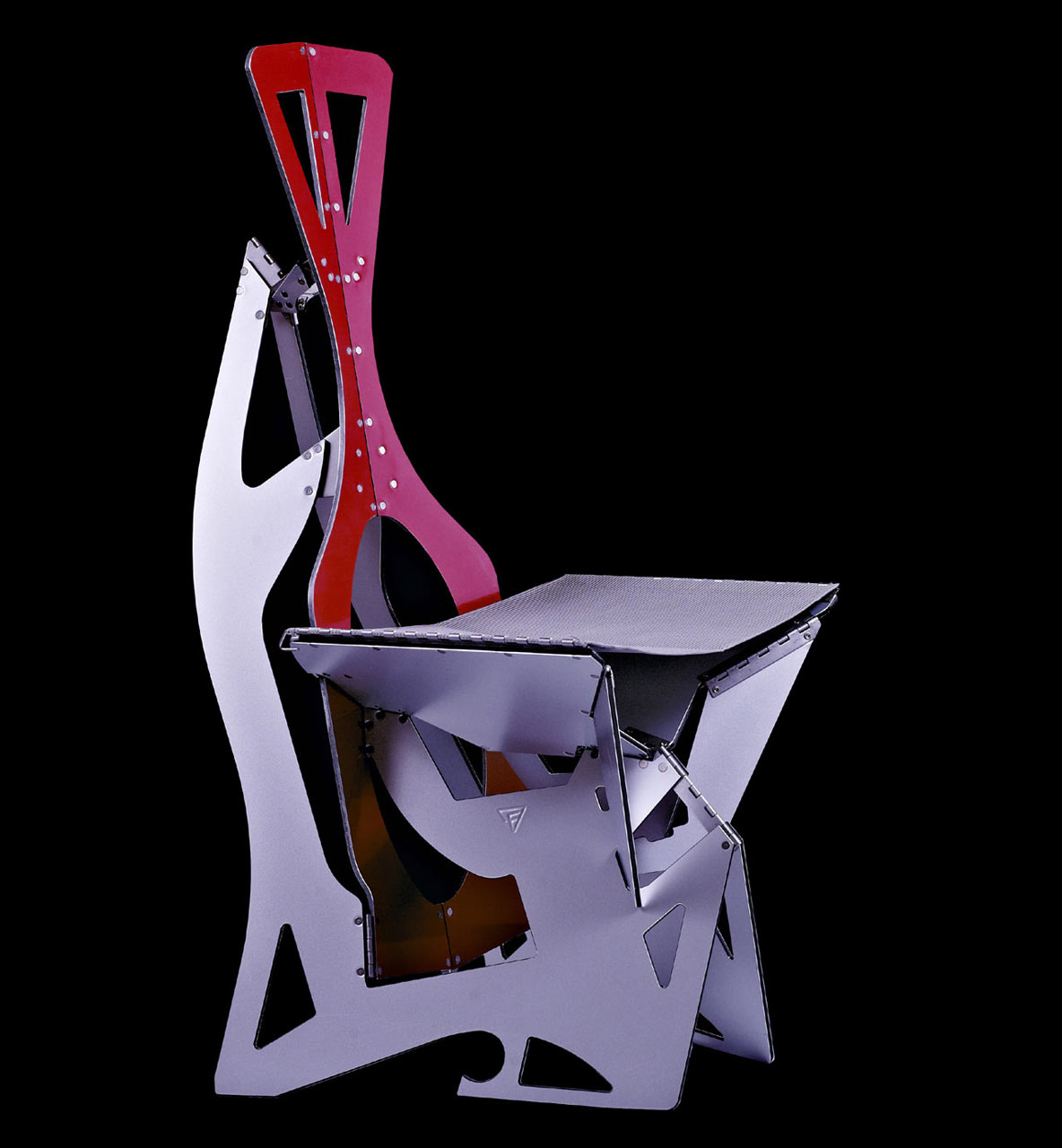

Folditure, founded by Alexander Gendell, set out to create a line of folding designs that were beautifully designed, while also sturdy and comfortable, and, most importantly, would practically disappear when folded up. The Leaf chair is the world’s thinnest folding dining height chair and it folds flat to less than 3/4 of an inch thick. The one above is limited edition version and it’s part of the permanent collection at the Brooklyn Museum. Last year we wrote about the Leaf chair and it never quite left our minds. Luckily, for this month’s Deconstruction, they’re taking us behind the scenes to show us how it’s done.

The results came as we amalgamated the manufacturing process with the creative process. We anticipated that building an unconventional product would require unconventional manufacturing as well. The design and manufacturing aspects evolved in parallel, feeding onto one another, with the main design concept and function leading the way. And while many of the steps in manufacturing our products are decidedly “hi-tech”, there are a lot of artisinal touches that help the process along, and are instrumental in the creation of this unique product.

A product starts with a moment of inspiration, and moves quickly to a model, sketch, prototype, 3D model – not necessarily in that order, and back and forth many times. Below is an early sketch of the leaf chair, which is overlaid on a geometry generator in 3D CAD. Note that in this drawing, the hanging “hook” is on the upper part of the backrest – an earlier idea. (As you can see on the current Leaf, the hook is on the bottom.)

Many prototypes are needed before the design can be produced. Below is a picture of one of the first prototypes of the Leaf. The frame material is 3/4″ plywood. It weighs approximately 25 lbs, and folds to a thickness of 2″. In comparison, the current Leaf weighs 15 lbs, and folds to 0.625″. Much of the design following this prototype involved fine-tuning the mechanism, geometry, materials and manufacturing – all in sync, to make the Leaf smaller, lighter, and compact enough to hang in a standard 24″ closet. The more form was following the function, the closer we got to that goal.

Different materials are tested out for their qualities. The current Leaf chair utilizes an aluminum composite panel frame, a material typically used for exterior architectural cladding. Made to resist weather for many years, strong yet relatively light.

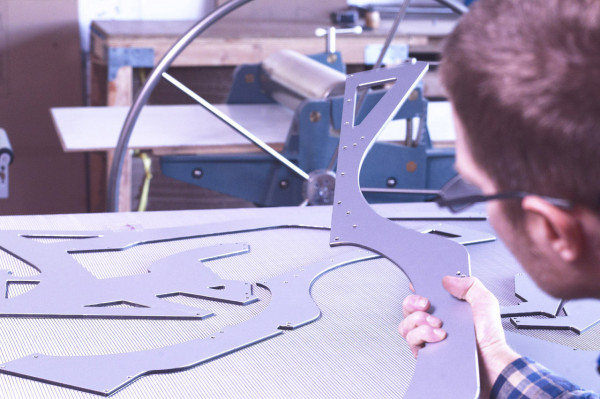

Many steps go into producing a single Leaf chair. The frame of the Leaf starts out in our shop as a sheet of ACP, that we cut and form on our CNC machine.

Each piece then is hand-finished and inspected.

Once the pieces are sorted, we emboss our logo.

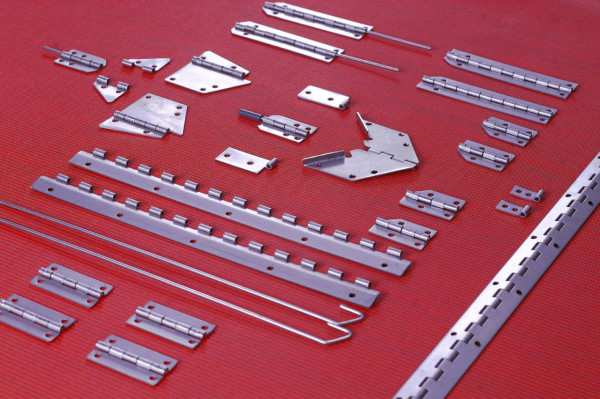

The frame pieces are joined together with custom made hinges that allow for smooth folding and unfolding. The hinges are cut by hand, formed, and holes are punched for the rivets. A single Leaf chair contains 26 hinge pieces of various shapes.

The hinges are cut and formed to extremely tight tolerances. Unlike other folding mechanisms which allow for some error, the geometry underlying the Leaf mechanism is unforgiving. We make our own hinges out of stainless steel. Each hinge is finished by hand.

Over 100 aircraft-grade stainless steel rivets are used to attach the hinges to the frame. Shown here is one of our pneumatic hand riveters.

The hinges are assembled with the aluminum panel pieces, and riveted together for an extremely tight bond. Here are the locking mechanism “butterflies” being made.

During final assembly, the chair is tested and adjustments are made to ensure smooth movement.

Finishing touches: the seat fabric is attached, as well as any optional laminates. The Leaf is inspected again before it receives a tag with a serial number.

The Cricket folding table is manufactured in a similar fashion. It has, however, many more pieces, and it is mechanically more complex. But it is all worth it, as the Cricket folds to 0.625″ as well, and so a set of 2 Leaf chairs and 1 Cricket table take up less than 2″ of hanging space.

The Leaf hanging!