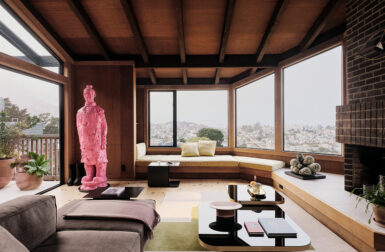

In this month’s Deconstruction, we get an inside look into the design and creation of Thos. Moser’s Cumberland Chair, designed by Adam Rogers. Part of the Cumberland collection, which launched in the fall of 2014, the dining chair is simple in form, void of any extraneous details, while at the same time being a piece of wooden artistry reminiscent of Danish modern design. The chair falls right in line with the company’s keen attention to detail and honest craftsmanship. Take a look as we get a glimpse into the process of how this chair came to fruition.

The chair was designed by Adam Rogers to exemplify the Thos. Moser design ideals: Simplicity of form + efficiency of design solution with an emphasis on proportion, scale + details; Elevation of craftsmanship + quality through visible joinery; and evidence of respect for wood as a natural and beautiful material.

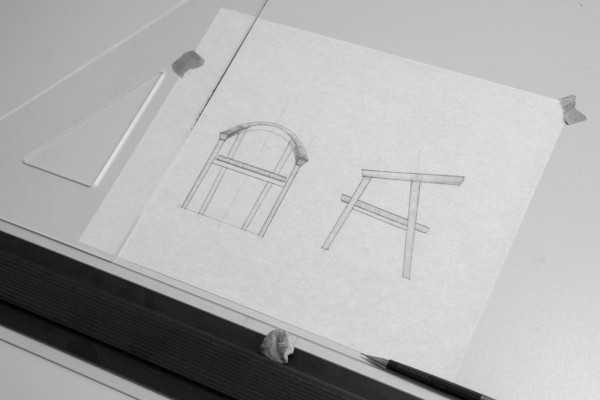

The process began with hand sketches.

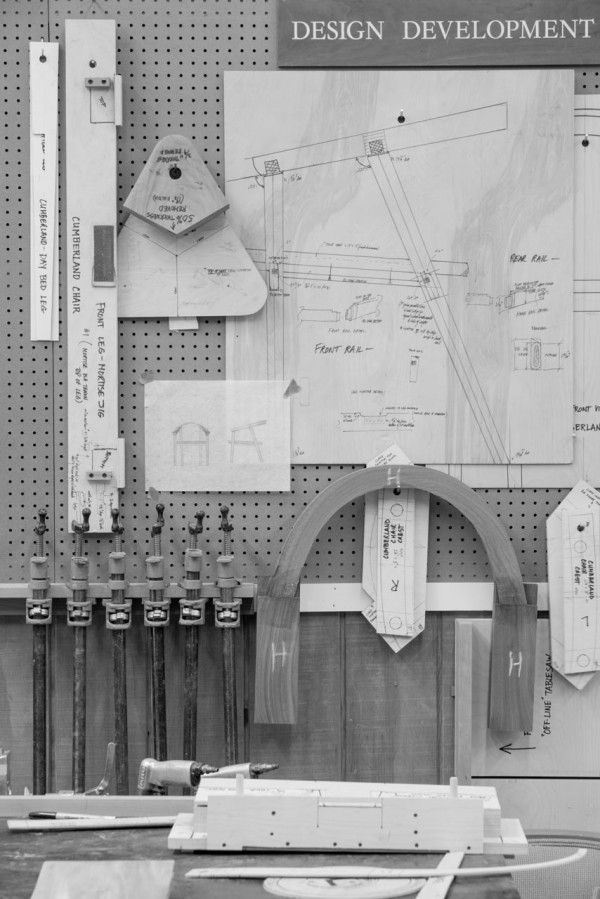

Once finalized, the design concept was rigorously prototyped to vet scale, proportion, comfort, application of joinery, etc. The bench is where most design decisions are made. The prototyping process is a collaboration between the design, engineering, manufacturing disciplines – all in service of the craft of woodworking.

Due to the geometry of the seat and the relationship to the continuous arm + crest rail, the saddled solid wood seat provides comfort without relying on the use of an upholstered foam seat.

After several iterations and improvements, a final prototype was produced and dry-fit for reverse engineering in CAD.

The chair was modeled, production drawings produced, and CNC programs written.

Once engineering was complete; a pilot run of chairs was run through the standard manufacturing process in the shop.

Tapered legs were turned for the four legs.

Atop the turned tapered legs sits the continuous arm and crest rail. This element is the sum of three pieces, a single solid wood steam bending at the back, joined with the collection’s hallmark visible finger joint to the arms.

Once the arms and crest rail are joined, the continuous piece is machined via CNC, then sculpted to its final shape by hand; illustrating the balance between precision machining and hand craftsmanship; high-tech and low-tech in collaboration.

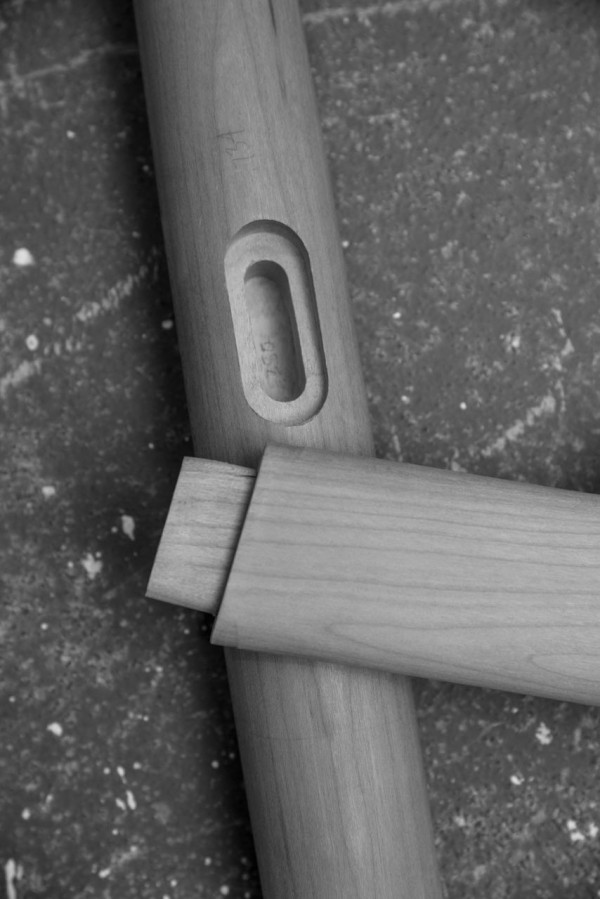

The rails that span the legs and support the saddled solid wood seat employ a double-housed mortise and tenon joint – achieving the desired simplicity without compromising strength.