Potter Lisa Jones wasn’t always holed up in ceramics studio. The owner and creative director of Pigeon Toe Ceramics actually started her professional life in graphic design and marketing before launching her much-loved company four years ago in Portland, Oregon. Jones focus on local craft and handmade sensibilities has earned kudos, as has her simple, modern-lined designs. The combination makes her wares unique and widely coveted. In today’s Designer Dailies, Jones takes us through a day of throwing pots, plus the thereafter.

A typical day begins around 8 AM. for me. I get up and head into work with my husband, who works at a bakery. I spend the first hour or two of my day sipping coffee, answering emails, and figuring out what the rest of day looks like. On this day, I was finishing up the costing for my Spring/Summer line, which came out on the 15th of March, and narrowing down/editing the catalog images of the new products. I have a graphic design background and still do all of the design work for Pigeon Toe, including the photos this season.

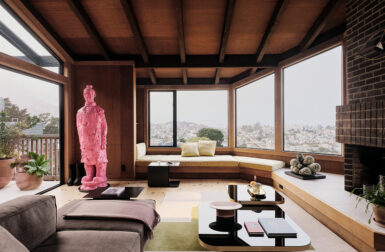

Once my emails and any other office-related tasks are complete, including any instructions or issues I need to troubleshoot with my office manager, I head into the studio, which adjoins the offices, showroom (pictured above), and shipping area of our new space. We just moved into a new studio on February 1, increasing our space 7 times!

I try to throw a few times per week at least. It keeps my skills sharp, keeps me thinking about new designs, and keeps me more involved in the day-to-day production. I still produce about 20 percent of all the ceramics coming out of our studio, sometimes more. The image above on the left shows the clay being centered on the wheel head; on the right is a big bowl in progress. I like clean, smooth surfaces, so those throwing lines were removed in the next step with what is called a rib.

On the left are pieces fresh off the wheel. You can see mini creamers, thimble cups, and a few custom pieces. On the right are the same pieces after they have firmed up into a state called “leather hard,” and trimmed with metal cutting tools. They are then stamped and the rims cleaned up with a wet sponge. We need to wait two-to-three days in between these steps (so this photo is more for illustrative purposes than an accurate one day snapshot).

I have a mold maker and caster on staff, so this is not usually my department, but we had a rush order for 30 faceted drawer pulls, so I took the reins on casting these while I was throwing. Every seven minutes a beeper would go off and I’d have to run over and drain the mold or remove them from it. The photo show of our slip in the middle of being reclaimed by our caster. We have great light all day long in the new space. I love the way the sunlight lit up the buckets.

This photo shows the pulls once they’ve dried out. I used a rough piece of sandpaper to level the bases of the pulls to make sure they sit flat before cleaning them up with a sponge.

Once my production manager unload the bisqueware from the kiln (pieces that have been fired once but not all the way to maturation, that need to be glazed and re-fired), we do our first inspection for defects — cracks, dents, warping, or the occasional piece out of spec (too small or big). Then the pieces head to the glaze room.

Once the load enters the glaze room, my two glaze techs being sanding the exteriors of the pieces and wiping them down for dust before pouring or dipping the wares in their intended colors. I try to also be involved in this process once in awhile so that I’m aware of any new issues we’re having related to glazing defects, supply levels, and quality. This photo shows thimble cups being wiped down after mint glaze has been poured on the inside.

After the glazing is complete (three-to-four hours for two people for a full load of product), they are loaded back on the cart and put in the kiln for the second firing. It will be unloaded about 30 hours later, then shipped to the customers.

Thanks, Lisa!