UK-based Green&Blue is on a mission to make homes and havens for wildlife. As a certified B Corp, they’re committed to doing this with consideration for people and the planet at the heart of what they do. From their Cornish workshop, they design and make a range of habitat products for different species with the Bee Brick, their innovative home for solitary bees, becoming a planning requirement within new builds in three counties across the UK – Cornwall, Brighton, and Dorset. We spoke to co-founder Gavin Christman to find out more…

Tell me a little bit about your childhood, education, and background in terms of how you first became interested in creativity, design, and sustainability.

I grew up on the edge of the industrial Midlands surrounded by glass foundries, metal fabricators, and ceramics factories. Though it was our industrial heartland, it’s woven together with stunning wild places, canals, and rivers, forging a lasting connection with nature. Growing up where I did, design and engineering are in my blood, as they are for so many from that area. Art college and then a design degree from Brighton followed before joining Dyson for what I thought would be my dream job.

How would you describe your project/product? And What inspired this project/product?

In 2005 I cofounded Green&Blue with my wife Kate and we set off to follow our dream of living and working in Cornwall. Our ambition was to manufacture wildlife products that would be made in the UK and designed to last a lifetime. As designers, our products are created in response to the challenges we see in the natural world. For example, the Bee Brick, a nesting site for solitary bees, is inspired by the way solitary bees have nested in brickwork or crumbling mortar for hundreds of years. Bee Brick seeks to replicate this for modern construction. As a company, our mission is to make homes and havens for wildlife, and to reconnect people with nature.

What waste (and other) materials are you using, how did you select those particular materials and how do you source them?

We make the Green&Blue range from locally sourced aggregates which are a byproduct of the China Clay industry here in Cornwall. Much of the stone extracted is used in industry but certain grades have very little commercial use. The concrete mix we have designed makes use of those aggregates, turning a waste material from a quarry just up the road from us into homes for wildlife.

When did you first become interested in using waste as raw material and what motivated this decision?

The innovation behind products like the Bee Brick lies in the fact that they can be used in place of standard bricks or blocks to make space for nature. Being designed for construction means the range needs to be strong, durable and trusted by the construction industry. This led us to concrete as a material, however we couldn’t ignore the environmental impact of cement. Knowing we had an incredibly strong and durable material in abundance on our doorstep allowed us to mitigate for this and create our own concrete mix using 75% recycled material.

What processes do the materials have to undergo to become the finished product?

Each day in our workshop, waste aggregates are combined with a cement binder, they’re mixed and poured into product moulds, vibrated and then cured overnight before being removed from the moulds the following day and processed, ready to be packed into boxes or onto pallets for delivery to construction sites.

What happens to your products at the end of their life – can they go back into the circular economy?

Our products are designed to last at least as long as the building they are installed in. I believe sustainability is primarily about making products that last as long as possible and have the least amount of impact during their manufacturing process. Should a building with our products reach the end of its life the brick and stone elements will be reclaimed, crushed and turned into recycled aggregates for further use in construction.

How did you feel the first time you saw the transformation from waste material to product/prototype?

The first Green&Blue product that used the waste aggregate concrete was the Bee Brick. However it took many prototypes before we had a product that worked, perseverance is key to product innovation! There’s a degree of magic and alchemy involved in creating the concrete mix, but as a team, we are motivated by these challenges, by problem-solving, and by trying to reduce our impact on the planet at every turn.

How have people reacted to this project?

The response to products like the Bee Brick and our other integrated nesting sites like Bat and Swift Blocks has been really positive and is only growing. As we become increasingly aware of the crisis in the natural world we need solutions like these to halt our biodiversity loss. Once common birds like swifts, sparrows and house martins have been added to the red list for birds of conservation concern and with the amount of construction happening, we have to rethink those spaces and ensure they provide for wildlife as well as humans. We have to remember to exist within nature rather than separately.

How do you feel opinions towards waste as a raw material are changing?

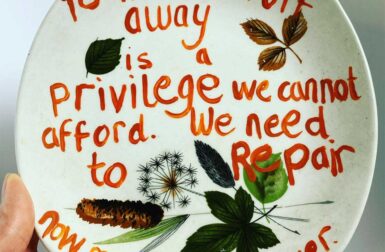

I believe people’s opinion of waste materials is changing but far too slowly, we seem reluctant to shift our lives away from consumer products that have little or no consideration for recycling. However, movements like B corporation and 1% for the planet are encouraging businesses to do better and to lead the way, we’re proud to be a part of that.

What do you think the future holds for waste as a raw material?

I think a fundamental shift from using virgin materials is critical to our future. We should aim to judge a product’s success by how much waste material is contained, by how little it takes from the earth’s resources. This is one of the biggest challenges we set ourselves at Green&Blue, to consider impact within every part of what we do.