London-based KITE is an up-and-coming eyewear brand that’s handcrafted by some of the best Italian artisans in the world. The designer behind the brand, Marcello Martino, aims to bring the highest quality materials and craftsmanship to each frame, which sends him to Italy on the regular to ensure his high-end standards are met. Their frames, which cover eyeglasses and sunglasses, are constructed in either metal or acetate in a time-consuming process that includes multiple quality checks. In this month’s Deconstruction, KITE shares the process of bringing their Broadwick eyeglass frames to life.

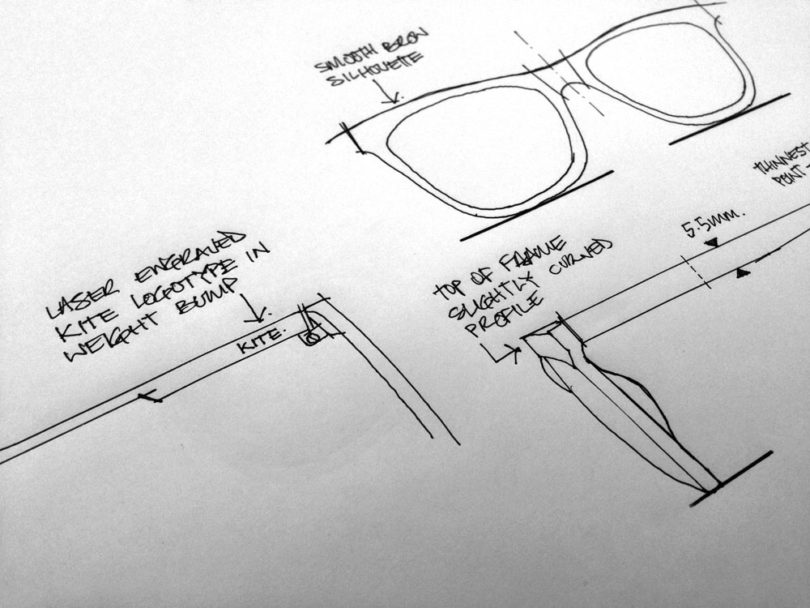

A KITE frame starts as a unique design by our London in-house design team before making its way to our makers in Italy. We explore color and light, form and function, to every last detail from nose-pad to temple-hinge, from concept-sketch to production.

We choose from a library of acetate sheet colors by Mazzucchelli, cellulose acetate innovators and glasses devotees. Think world-leading, game-changing, fantastic plastic.

[In 1849 the Mazzucchelli family started a company that was all about innovating with new materials. They started playing with naturals, then celluloid — the first ‘thermoplastic’ — before moving on to cellulose acetate and bioplastic, derived from sustainable wood and cotton fibers.]

The sheets of acetate are sliced into meticulously measured strips, each prepared to be transformed into a hand-finished frame.

The Mazzucchelli acetate strips are cut with millimeter precision to create the frame silhouette, and intricate detailing including cushioned nose-pads, tapered temple tips, and lens groove.

We chose to double the industry standard time each frame spends being polished… that’s double the glorious luster. Our freshly cut frame fronts are tumble-polished in birch wooden beads for 10 long not-impatient days. The gleaming object that emerges has a smooth as silk touch and sculpted fluidity.

Whilst the frame fronts are undergoing the polishing process, we move the making to our temple arms. Here they are reinforced with a stainless steel wire-core to deliver ultimate comfort, durability, and the ability to customize the fit to each wearer.

Whilst simple and easy on the eye, a mix of high-impact machinery and precision welds add exciting engineering details. Custom-designed rivets are inserted to secure the three barrel-hinges and teflon-coated screws for super-resilience, because a KITE is built to last.

More work by hand. Testing, detailing, finishing. Our rigorous 10-step quality-control takes time, nothing is left to chance. We strive for every frame to leave our workshop with faultless perfection.

Each frame is given a final hand-polish for longer lasting luster by carefully holding the frame against a smooth polishing disk.

Human eyes and hands check, polish, check, adjust, and check again.

Frames are carefully packed before they take flight to London, where they were first conceived. It’s like coming home.