We’ve shared our love of Swedish brand BAUX and their acoustic wall tiles and panels, for not only their sound absorbing qualities but also the really cool and colorful geometric patterns you can create. With forests aplenty in Sweden, it’s only natural that Swedish designers look to them for inspiration and that’s just what the group who formed BAUX did. They felt building materials should be both functional and beautiful without compromising environmental standards. The idea for BAUX tiles and panels came together when they began working with Träullit, a family business that uses cement and wood wool (wood shavings) to make boards and panels. Those two simple materials are the backbone for these environmentally-friendly acoustic components. Let’s have a look at the process in this month’s Deconstruction.

The wood is collected outside the factory in Småland, Sweden. This way, we can minimize the environmental effect since it is local.

The spruce wood is stacked and dried outside the factory.

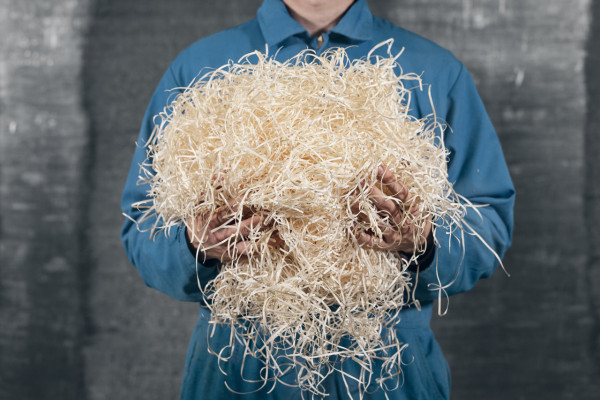

The spruce is cut into smaller pieces and ground down into wood wool.

The spruce wood wool is then ready to be blended with water and cement.

Water is added.

Cement is added.

The blend of wood wool, water, and cement is poured into molds. The molds are stacked and stored to dry.

Dried wood wool cement is then cut into smaller pieces and geometric shapes.

Baux Acoustic Tiles in the Hexagon shape are waiting to be spray painted in one of the many colors that are offered.

The much larger Baux Acoustic Panels are milled to create interesting patterns on each one.

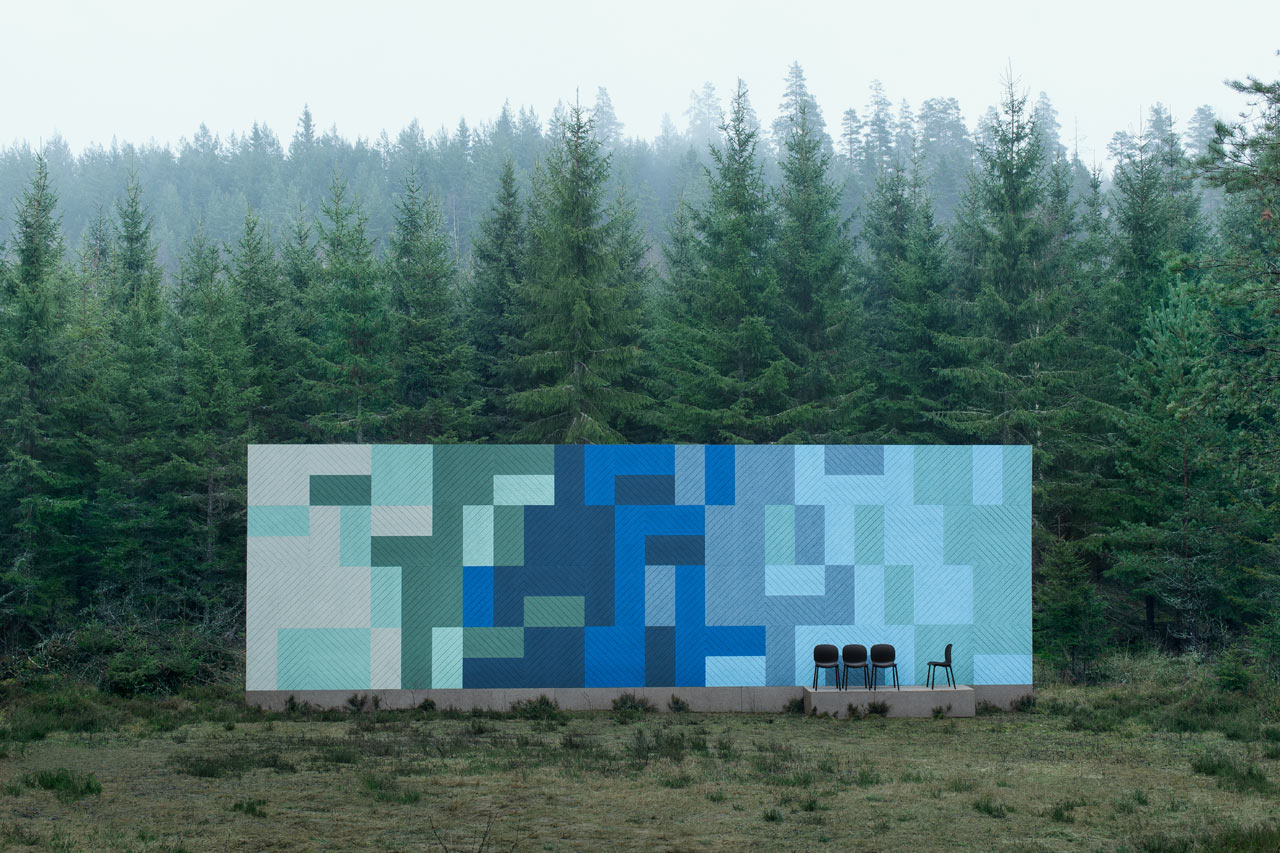

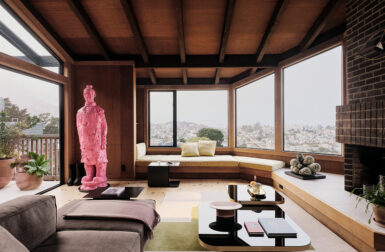

By combining shapes and colours, you can create any pattern with Baux Acoustic Tiles.

Baux Acoustic Panels can be used to rejuvenate the largest of spaces.