When Design Milk visited Denmark recently, we were lucky enough to get a peek inside the factory that produces some of the legendary designs that the Republic of Fritz Hansen has been making since 1872. Sitting on the outskirts of Copenhagen, a ubiquitous building houses skilled craftsmen and some machines that focus on impeccable quality control and consistency that is second to none.

Arne Jacobsen’s Series 7™ chairs are synonymous with the Fritz Hansen name and still remain one of the most sold chairs from the brand. The chair comes in nine different types of wood and a multitude of colors, along with a few variations like a swivel version, a bar stool, and one for children. Take a look at how this iconic chair is made…

They start with super thin layers of veneer in whichever wood they are producing at the time. Each chair is made from layers of veneer like in these stacks that are then pressure molded together.

Each piece of veneer is hand-sorted and painstakingly matched together by the grain. The similar pieces are joined together to make larger sheets.

Some grains just don’t make the cut and these are some examples.

And then some are too cute to not hang up!

Layers of veneer get cut down to the basic shape.

The layers of veneer are sandwiched between two matching sheets of veneer that will make up the exterior of the chair.

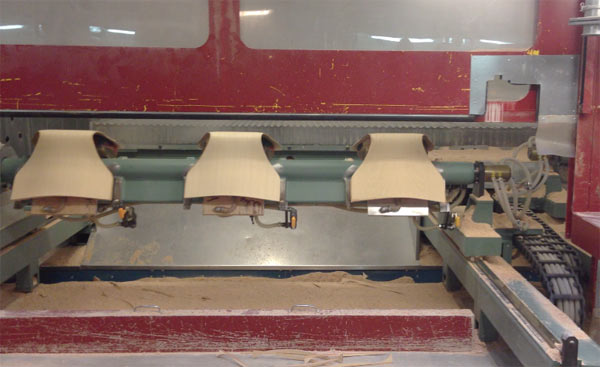

One of the machines that pressure molds the layers together.

Molded seats going into a machine to cut the curves into the edges.

And after!

Some additional hand sanding going down.

A row of seats getting varnished.

Rows and rows of the finished seats ready for stands to be attached.

Metal stands waiting to be attached to the various seats.

A wall of color options that have been available over the years.

Thanks Fritz Hansen!