For this week’s Friday Five, we head to London to check out Materials Council, an independent firm founded in 2012 by Ian Hunter, Brad Turner, and founding partner, Architonic. Brad and Ian are both from the northeast England and have backgrounds in industrial design which lead to their love of materials and manufacturing processes. The duo operated the world’s largest materials library when then became materials researchers for Foster + Partners architects where they were able to advise the architects about materials for their projects. After years of acquiring knowledge in the materials field, they realized the design world was lacking a resource about materials and manufacturing so they established Materials Council to offer insight to practices of all sizes, as they needed it. See what material-based picks Brad and Ian chose and why.

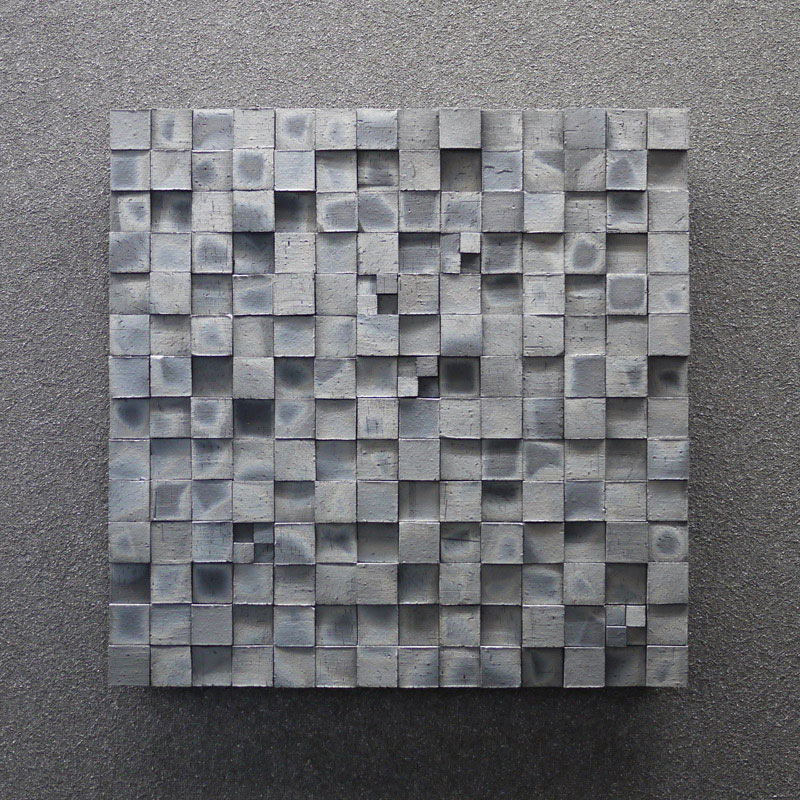

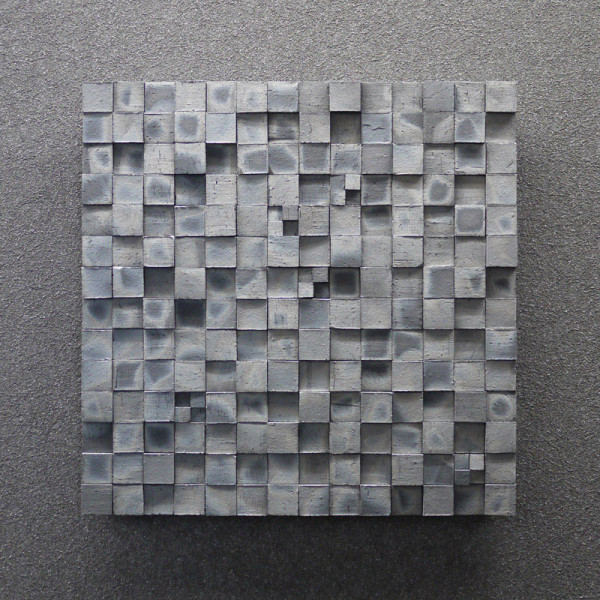

1. Concrete

We love a good bit of concrete! It’s a remarkably versatile material in its applications, performance, and appearance. It can be the thin skin of a building, protectively enveloping it, or thick structural walls and foundations, regulating the temperature of the internal environment. Industrial, monolithic and grey, revealing the scars of its formation, or a pristine polished surface of shining aggregate.

Sustainability-wise concrete does have quite a bad reputation, and indeed its production is responsible for 5% of all global CO2 emissions, but that’s simply due to the massive quantities it is used in. When directly compared to other materials, its embodied carbon and the performance benefits it offers, it compares very favourably. And with the development and increasing adoption of cement replacements (such as fly ash and blast furnace slag), CO2 absorbing magnesium-based cements, or the use of void formers and recycled aggregates, the environmental impact of concrete is being reduced further.

Photos courtesy of GlassX

2. Phase Change Materials

Phase change materials (PCMs) offer a low-tech, low-cost method of passive heat regulation, reducing the energy consumption of our buildings through powered air conditioning and heating. PCMs absorb excess internal and external heat and release it again as the temperature drops and heat is required.

They are being used in a range of products including plaster board and insulating glazed units, offering a solution to materials with a low thermal mass. When used in glazed units they can be used more congruously across a glazed facade, increasing its thermal performance while also permitting natural light.

We have a little vial of phase change wax on our desks. When that melts it is officially too hot in the studio and time for a game of table tennis in the sun!

3. Bamboo

Timber is a fantastically sensuous and sustainable material, yet even this most fundamental of natural construction materials can be trumped. While timber is a renewable material, due to its long growth period its planting and harvesting must be properly managed to ensure it is used sustainably. Bamboo is rapidly renewable, with some species of bamboo growing over 1m in a day. It is available in the form of standardised panels, boards, veneers and blocks, comparable to commonly available timber formats, and is increasingly taking the place of timber.

It has long been used in its natural form in eastern cultures structurally, for example as scaffolding, but is now also being adopted for structural use by contemporary architects and designs, such as Vo Trong Nghia Architects of Vietnam.

Photo courtesy of Architectural Titanium

4. Crystal Titanium

Rolls Royce developed a technique to manufacture turbine blades for their jet engines by ‘growing’ a single crystal of a metal super alloy, creating blades of unrivalled performance designed to operate at 200ºC above their melting point. Architectural Titanium of Kansas, USA, developed a similar process to create a unique decorative appearance on titanium sheet by altering the crystalline structure of the material.

Titanium sheet is placed in a vacuum and subjected to a precisely controlled temperature cycle, taking it to almost its melting point. This causes the natural crystal structure of the titanium to enlarge and re-orientate across the thickness of the sheet and becoming visible on its surface. This new crystal structure creates a unique radiant appearance as each crystal responds differently to the light.

Architectural Titanium are also pioneers of fashion, making the word’s first titanium dinner jacket especially for Frank Gehry.

5. Japan

Japan: a nation steeped in tradition and dedicated to quality and technological progression. From designers to manufacturers to contractors, their attention to detail and precision is to be admired.

Japan is a fantastic source of unique and fine materials, both old and new. From the most luxurious Urushi lacquers, applied in over 50 layers, and traditional Ibushikawara clay roof tiles, to the latest crystallised glass ceramics. Renowned for its craftsman and traditional making skills, as times and needs have changed so have their craftsmen. Companies previously famed for producing the finest sword blades now manufacture and fabricate architectural metalwork of unrivalled quality.

Despite these impossibly high standards, the overarching philosophy and aesthetic viewpoint of ‘wabi-sabi’ is something for the perfectionist in all of us to aspire to: nothing lasts, nothing is finished, nothing is perfect.